Flawless replenishments

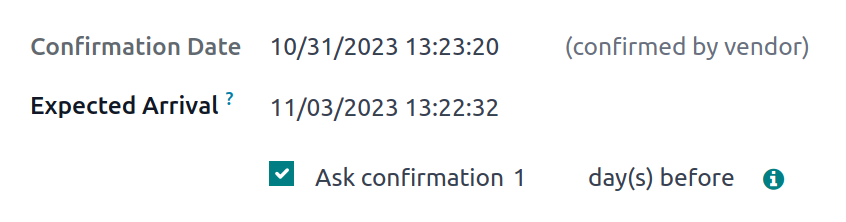

Never run out-of-stock with smart replenishment strategies like min-max rules, MTO, or the master production schedule. Let Cloud ERP propose, or trigger purchase orders automatically. Then automate vendor follow-ups to minimize communication risks : PO acknowledgment, receipt schedule confirmation a few days before, etc.

Speed up receipt, quality control and storage

Control incoming and outgoing shipments with push and pull rules, GS-1 codes, and customizable routes.

Use put-away strategies to optimize your storage: slow-fast movers, ABC analysis, cross-dock… all you need to reduce the number of parts moved, and distances.

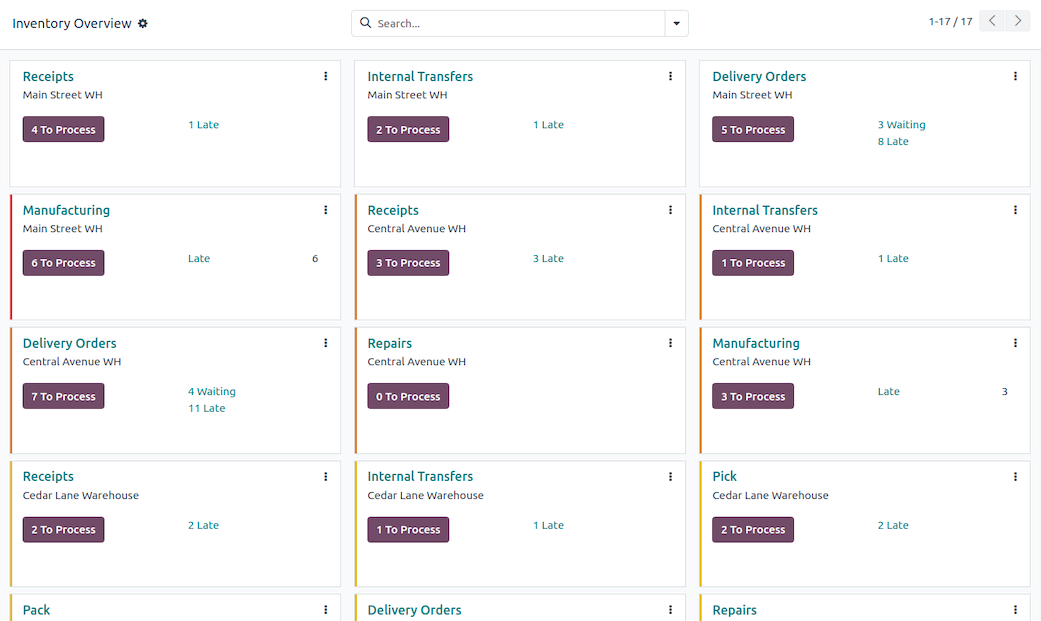

Optimize your warehouse

Real-time inventory management with all the features: serial numbers, lots, packaging, reservation strategies, cycle counting, KPIs, and more…

Blazing-fast inventory lookup: instantly know the location of all your products across multiple warehouses or multiple companies.

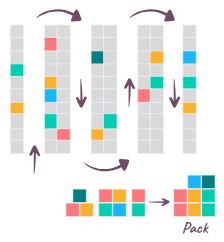

Minimize picking movements

Choose the right strategy for you: single, cluster, wave, or batch picking. Trigger goods to release using multiple reservation strategies. Implementing the rights strategies allows to pick and pack 30% extra products with the same team.

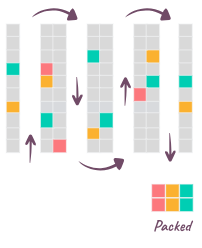

Wave picking

Launch picking orders per aisle, or area, and regroup at packing zone. Ideal for large warehouses.

Cluster picking

Pick multiple orders in one trip, and prepare orders as you pick, to save time at packing. Ideal for small products.

Batch picking

Regroup multiple orders in one picking, and consolidate at the packing zone.

Packing has never been easier

Cloud ERP integrates with carriers to print shipping labels, quality controls, and different packing units such as parts, boxes, pallets, and more.